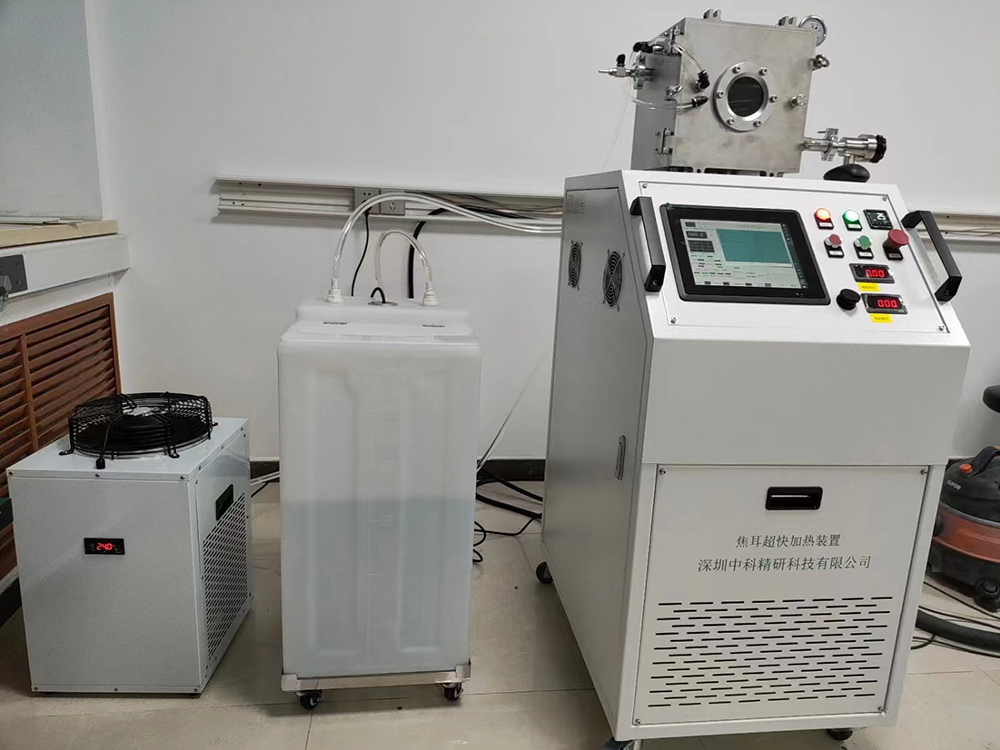

High-temperature Long-Time Joule Heating Device

Product Overview

This device is equipped with a stainless steel vacuum chamber and a chiller, enabling sustained high-temperature operation. Its advantages include simple operation; simply specify the heating and cooling durations, target temperature, and holding time. The device can automatically execute the preset program, featuring six independently controlled temperature zones and adjustable current control stages for precise heating.

Advantages

Ultra-fast sintering speed((seconds);

Long sintering time (hours);

Intelligent temperature range selection(100-3000C segmented measurement);

Multiple sample testing (sample slotcapacity can be expanded and customized);

Precise temperature control, within 1°C ofthe target temperature.

Application Scenarios

Carbon materials

Ceramic materials

Battery electrodes, solid-state electrolytescatalytic materials

Two-dimensional materials, high-entropymaterials, MOFs, 3D printing materials

Metals and composite materials, etc.

Sample State:

Films

Powders

Bulk materials

Battery materials

CatalystsGraphene and nanomaterials

Ceramic materials

High-entropy alloys and compounds

Product Parameters

| Temperature Range: | 100-3000℃ |

| Electrical Specifications: | 220V, 18KW (customizable) |

| Overall Dimensions: | 70*70*150cm |

| Sample Diameter: | 40mm/30mm/20mm/10mm |

| Sample Thickness: | Up to 10mm |

| Temperature Range: | Up to 3000K |

| Vacuum level: | 6×10^-2 Pa |

| Chamber Operating Mode: | Vacuum, Ambient Inert Gas/Nitrogen Cycle (optional)/Ammonia Cycle (optional) Protection |

| High-Temperature Sintering Platform: | Copper, Graphite |

| Temperature Probe: | Infrared Non-Contact, Accuracy ±1% FS |

| Cooling Method: | Water Cooling (Chiller) |

| Electrode Material: | Copper |

| Operating Method: | Touchscreen Operation |

| Gas Line Specifications: | 1 Inlet, 1 Exhaust, 1 Vacuum |

| Pulse Parameters: | 100 pulses/ms |

| Heating Rate: | Over 20000℃/s |