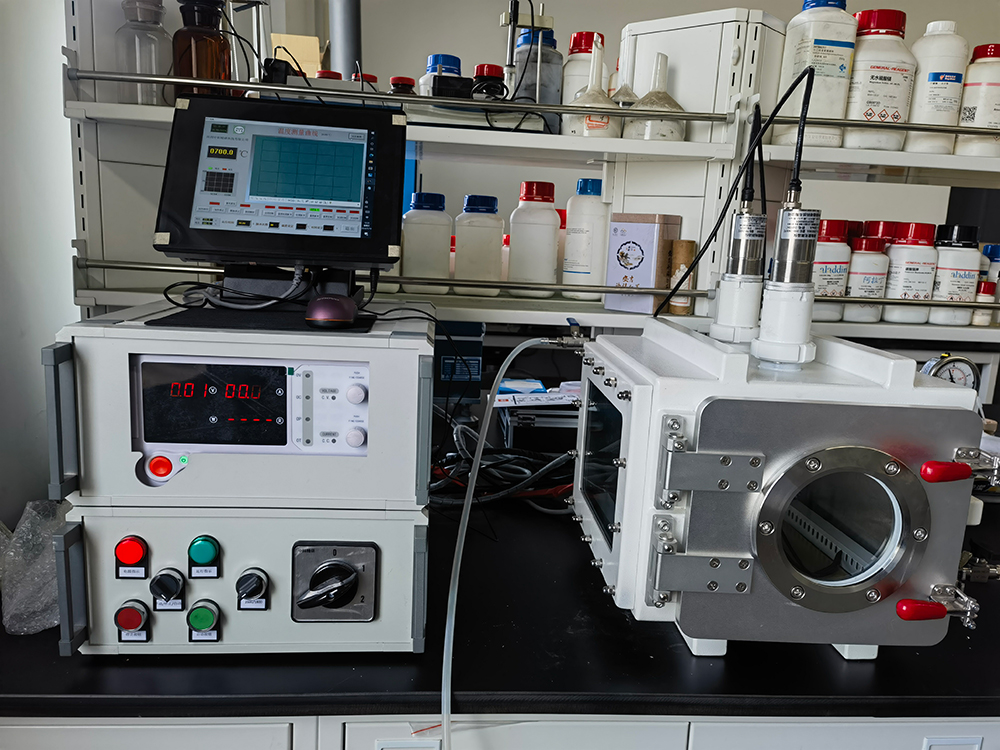

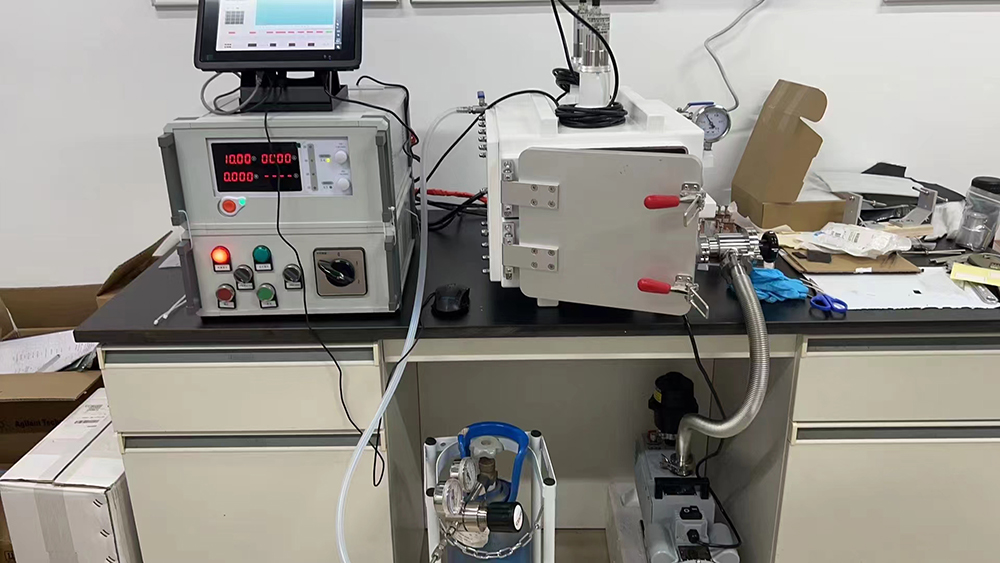

High-temperature Shock Joule Heating Device

Product Overview

By integrating fast heating with pressure control technology, this device achieves ultra-fast heating within 0 to 10 seconds, producing ultra-fast thermal shock effects. It enables the observation of changes in the material's structure and properties under conditions of extreme temperature variations and intense thermal shock, enabling the ultra-fast synthesis of small molecule nanomaterials

Advantages

Ultra-fast sintering speed (seconds);

Sintering time (minutes)

Strong bonding force, ensuring more secure powder bonding

Intelligent temperature range selection (100-3000℃ segmented measurement)

Can test 2-4 samples at once

Sintering Methods: Contact, Thermal Radiation, Sandwich

Application Scenarios

Carbon materials

Ceramic materials

Battery electrodes, solid-state electrolytes, catalytic materials

Two-dimensional materials, high-entropy materials, MOFs, 3D printing materials

Metals and composite materials, etc.

Sample State

Films

Powders

Bulk materials

Battery materials

Catalysts

Graphene and nanomaterials

Ceramic materials

High-entropy alloys and compounds

Product Parameters

| Temperature Range: | 100-3000℃ |

| Power: | 1800W |

| Electrical Specifications: | 220V, 18KW (customizable) |

| Overall Dimensions: | 100×60×60 cm |

| Sample Diameter: | 40mm/30mm/20mm/10mm |

| Sample Thickness: | Up to 10mm |

| Temperature Range: | Sample Platform: Up to 3000℃ |

| Vacuum level: | 6×10^-2 Pa |

| Chamber Operating Mode: | Vacuum, Ambient Inert Gas/Nitrogen Cycle (optional)/Ammonia Cycle (optional) Protection |

| High-Temperature Sintering Platform: | Copper, Quartz Tube |

| Temperature Probe: | Infrared Non-Contact, Accuracy ±1% Full Scale |

| Electrode Material: | Copper |

| Operating Method: | Touchscreen Operation |

| Gas Line Specifications: | 1 Inlet, 1 Exhaust, 1 Vacuum |

| Pulse Parameters: | 100 pulses/ms |

| Heating Rate: | Over 20000℃/s |